What are the types of gas leaks The importance of gas detectors

Gas leaks are a frequent challenge that companies face during production, storage and transportation, including compressed, flammable and toxic gases. These leaking gases often lead to fires, explosions, personnel poisoning, energy waste, equipment failure, and harsh environmental impacts.

So what are the types of gas leaks? For different types, how can we effectively prevent it?

Gas leaks are usually categorized into two types: small-hole leaks and large-area leaks.

When a gas leak occurs, turbulence is generated at the leak, which produces sound waves related to the frequency of vibration, the size and geometry of the leakage hole. Larger leakage holes have a lower frequency and can be heard by the human ear. Smaller leaks, however, have a higher frequency, over 20 kHz, which is ultrasonic, but not audible to the human ear.

Generally speaking, gas leakage detection is for small leakage holes, such as valves, pipelines, reactors, tanks, etc. Small holes or sealing failures in the relevant connection parts lead to long lasting gas leakage.

According to the characteristics of the source of gas leakage, form and location of different situations, gas leakage can be divided into sealing components of the leakage, pipeline or tank leakage and safety pressure relief components such as pressure reducing valves and other leakage of three models.

01、Leakage of sealing components

Coal, petroleum, chemical and other major gas leakage accidents, most of them are due to sealing installation, design is not reasonable or seal aging failure. The sealing of the gas is generally through the sealing surface between each other close contact thus reducing the gap between the connected parts of the equipment to achieve, but due to the inability to completely eliminate the connection gap between the components, so the theoretical sealing of the gas leakage will always be there.

02, pipeline or tank leakage

Due to the aging of the pipeline or tank, material strength reduction, or by corrosive substances, as well as the existence of gas pressure or pressure changes, it is likely to lead to a part of the pipeline or tank breakage, resulting in gas leakage accidents. Generally as long as the pipeline, tanks and other pressure vessels in strict accordance with the mandatory use of the period of scrapping and replacement, basically very few problems will occur.

03、Safety pressure reducing valve and other pressure relief components of the release

Pressure relief elements generally include three types of safety pressure reducing valves, pressure reducing valves and safety valves, are usually used as steam, gas or vapor control or pressure relief discharge system. This type of gas relief, unless the aforementioned valves are damaged, is mostly used as a treated exhaust gas discharge or as a pneumatic power system.

How to effectively prevent gas leakage?

1、Equipped with portable gas detector Strengthen the safety inspection

Staff should strengthen the safety inspection, equipped with portable gas detector, timely detection of leaks and effective treatment, thereby reducing accidents and casualties.

Chisholm Electric portable gas detector, a wide range of small and lightweight, suitable for a number of places.

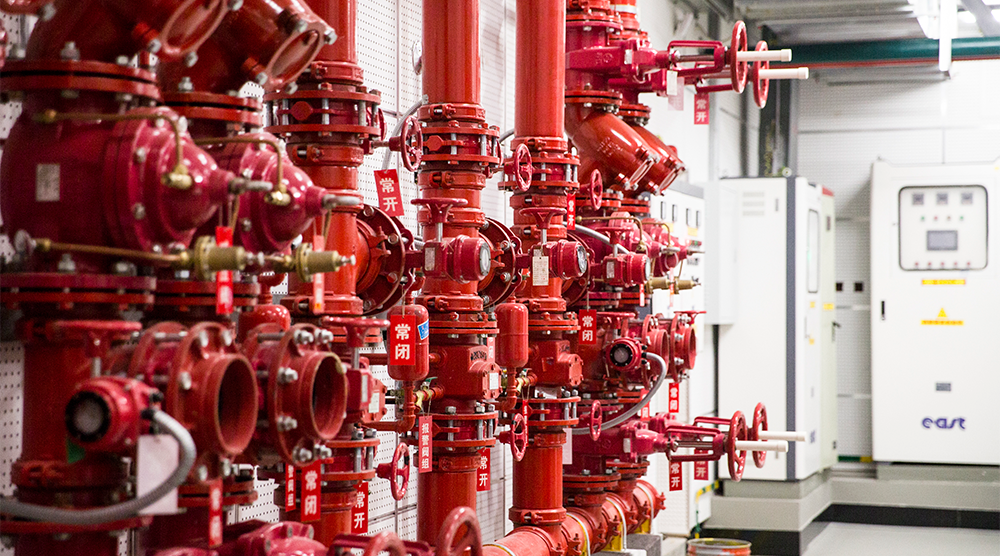

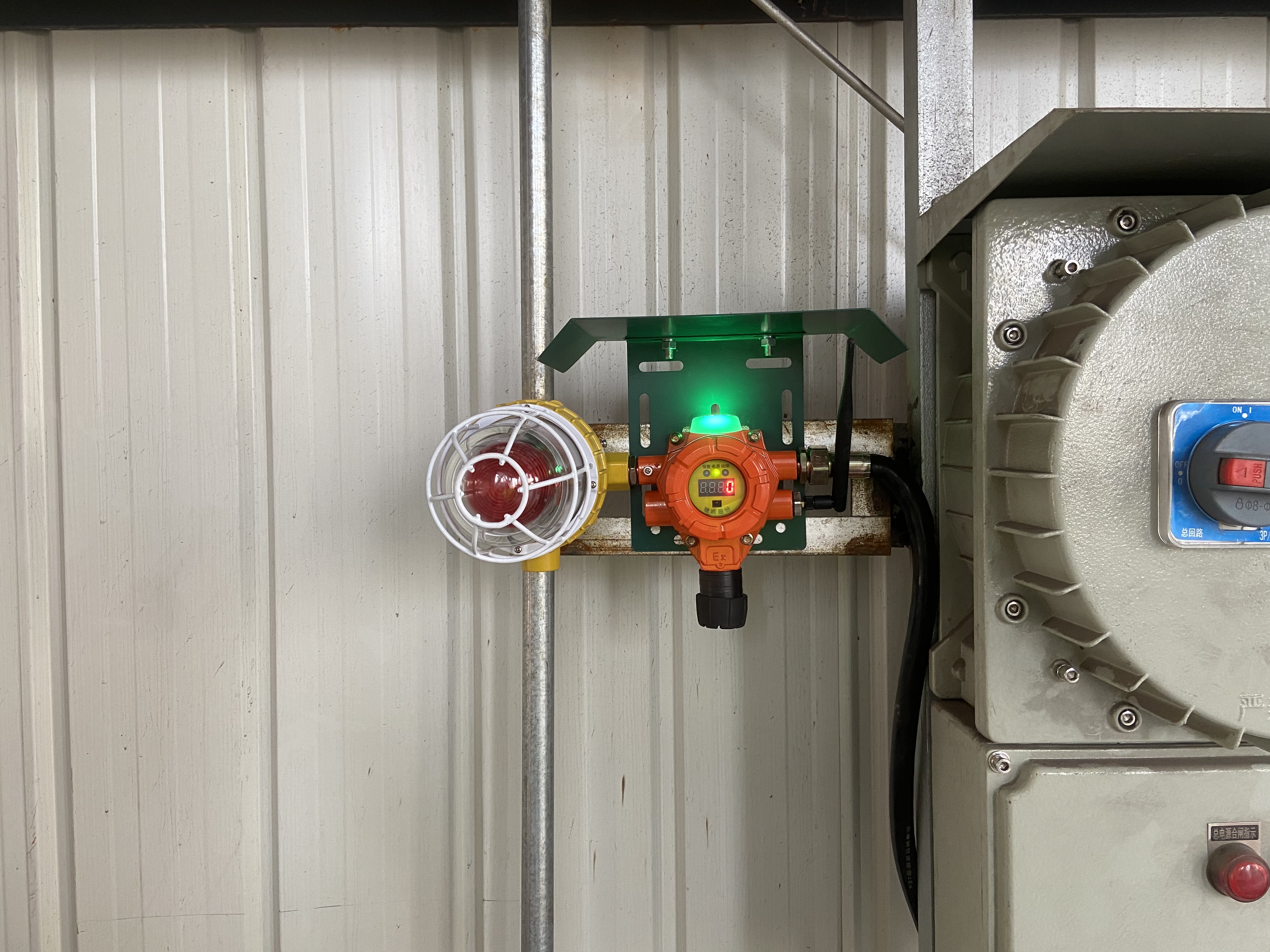

2、Installation of fixed gas detectors

In prone to toxic and hazardous gas leakage places to install fixed gas detectors, real-time monitoring of gas leakage concentration. Once the gas leakage concentration to be measured reaches or exceeds the preset value, the alarm will immediately send out sound and light alarm signals, but also can be linked to solenoid valves, fans and other equipment to prevent accidents.

3、Regular maintenance and timely repair

Users need to regularly calibrate the combustible gas alarm and toxic gas alarm to ensure accuracy and sensitivity. When the instrument malfunctions, you should ask professionals or contact the manufacturer for maintenance, do not disassemble the instrument at will.

4、Improve the safety awareness of the preparation of emergency plans

Enterprises should be compiled production safety emergency plan to improve employee safety awareness and enhance emergency response capabilities.

Henan Chicheng Electric Co., Ltd (Chicheng Electric) was founded in 2004, is a manufacturer and supplier of gas safety products and system solutions for the global market. The company's main products are: gas detection and alarm instruments, alarm control systems and supporting, intelligent sensors, safety and environmental protection analysis instruments and systems, safety monitoring software systems, intelligent cloud platform, etc., which are widely used in electric power, electronics, metallurgy, chemical industry, petroleum, coal, mining, railroads, pharmaceuticals and scientific research institutions and other fields.