CHICHENG Electric Gas Detector Challenges 100℃ Extreme Temperature Difference

Purpose of high and low temperature test

Gas detectors for the most part operate in a much harsher environment compared to natural temperature variations. This means that the instrument must be able to ensure that, even in harsh environments can be stable and reliable normal operation, especially in some important areas, a slight error, may cause major losses, threatening people's lives and property safety. Such as petrochemical, urban underground comprehensive pipeline corridor, hazardous chemicals and other fields.

High and low temperature test belongs to the environmental reliability test, mainly examines the operation of gas detectors in extreme temperature environment. Therefore, it is necessary to examine the adaptability of the product for use and storage under hot and humid conditions, observe the impact of the test sample at a constant temperature, no condensation, high humidity for a specified period of time, and evaluate the ability of the test sample to withstand hot and humid conditions in an accelerated manner.

High and low temperature test requirements

◆ The surface of the product should be free from damage, deformation and other defects. If the surface is coated, there should be no peeling, blistering or discoloration of the coating.

◆ For plastic parts, the surface should be free of cracks, blisters and deformation.

◆ For rubber products, there is no aging, bonding, softening and cracking.

◆ There is no flowing phenomenon in the welding part of product parts.

◆ The performance data and structure function of the product meet the requirements of the technical conditions, and there should not be any other defects that hinder the normal work of the product.

The process of high and low temperature test of Chicheng Electric

◆Test instrument: fixed gas detector

◆Test environment: 70℃/2 hours high temperature test

◆Test environment: -40℃/2hours low temperature test

After the severe test, the gas detector meets the normal work in the environment of -40℃ to 70℃.

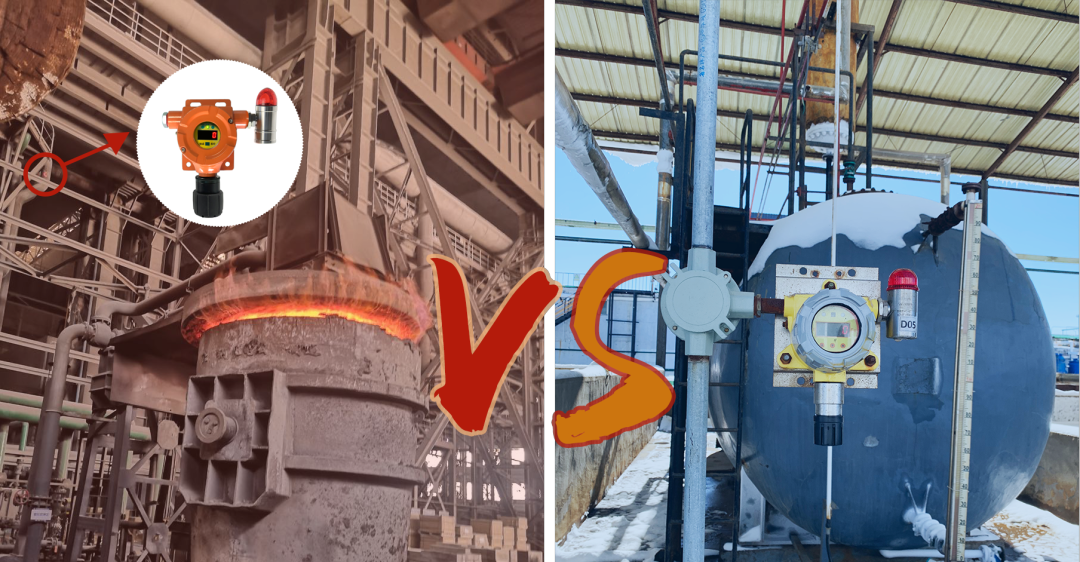

Gas detectors are mostly installed in petroleum, chemical, metallurgy, pipeline corridors and other large industrial sites and gas, food and beverage, animal husbandry, agricultural greenhouses and other industrial and commercial sites, the environment temperature is more extreme and rapid changes, so a strong ability to adapt to high and low temperatures is essential.

Chicheng Electric gas detectors use high-quality sensors to effectively protect the sensitivity and reliability of the instrument. In the face of complex and changing gas environment, the instrument in addition to high and low temperature test, but also aging test, salt spray test, explosion-proof test, hydraulic test, drop test, etc., only after a thousand refinements, in order to create a good product!

Chicheng Electric strictly control each production and quality control links, only all aspects of performance are qualified, in order to circulate in the market, to meet the real challenge!