At present, the global scope of the new round of technological revolution and industrial change is breeding rise. Vigorously promote the deep integration of information technology and industrialisation, is the new era under the background of accelerating the new industrialisation, seize the opportunity of the development of digital economy is an important path. Integration of the two is the high degree of integration of informatisation and industrialisation, which is to drive industrialisation with informatisation, promote informatisation with industrialisation, and take the road of new industrialisation. Through the information drive, drive equipment upgrading, create a new type of enterprise ability, highlight the core competitiveness of enterprises, through the high degree of integration of information technology and industrialisation, to achieve the maximisation of enterprise advantages, to achieve cost reduction and efficiency, source saving and flow opening, innovation and development, and wisdom to change the number of the purpose of the turn.

The fusion of the two is an important part of the national strategy ‘Made in China 2025’, which aims to promote enterprises to improve the level of industrialisation through information technology and achieve transformation and upgrading. Enterprises to carry out the fusion of the two can promote the optimal allocation of resources and production process of green, low-carbon, strengthen the collaboration with the industry inside and outside, share information resources, enhance the competitiveness of the entire industrial chain, help enterprises to achieve sustainable development.

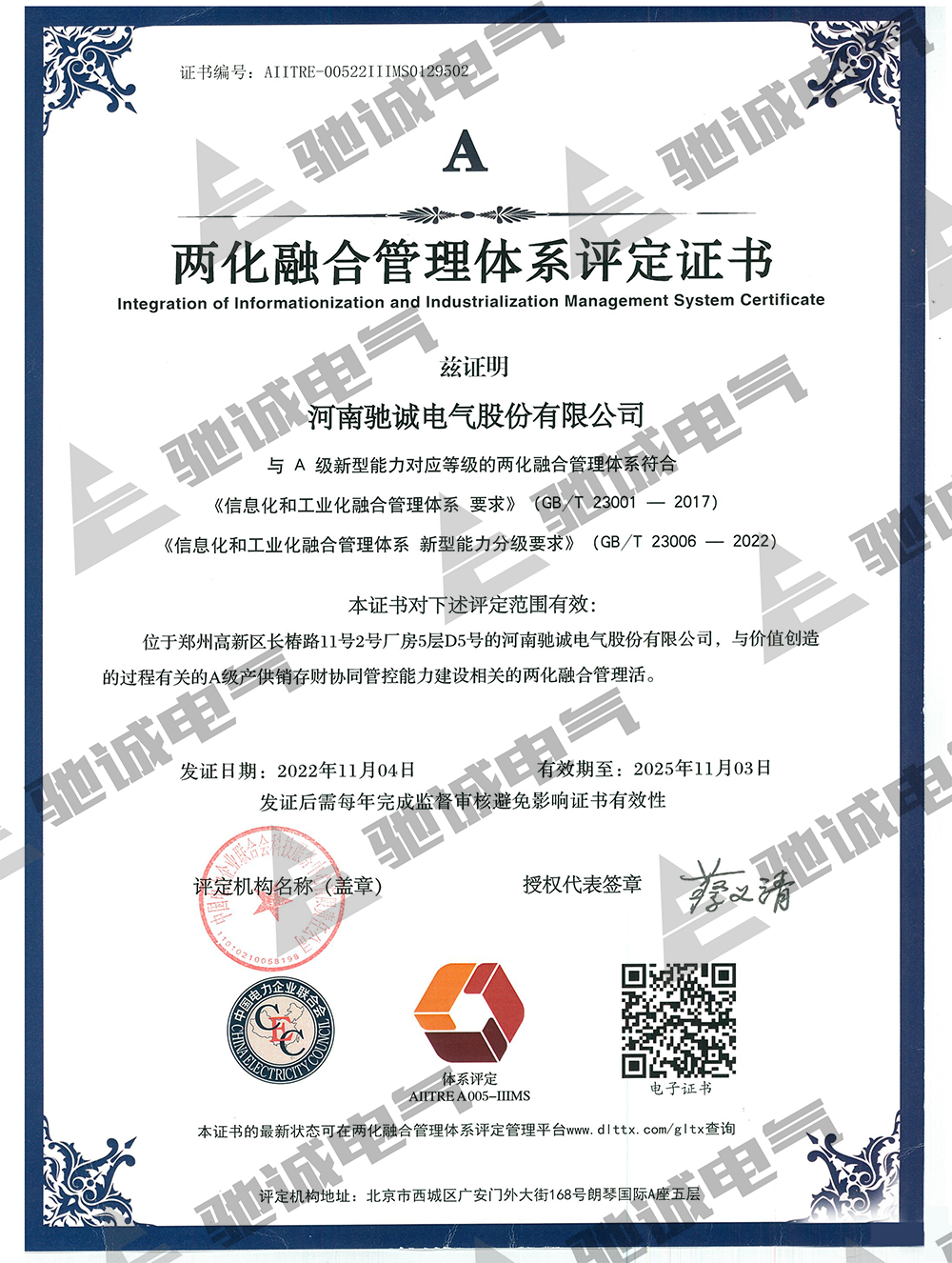

Recently, China Electricity Council Science and Technology Service Centre Limited Liability Company assessment expert group visited Chicheng Electric, the enterprise two integration management system to supervise and review. Zhao Jing, Vice General Manager of Chicheng Electric and the persons in charge of each department warmly received and actively co-operated with them.

A number of fully automatic intelligent production line running in an orderly manner, calibration, calibration, aging and other data in real time on the LCD screen, the entire production process is more intuitive, three-dimensional, transparent. Automatic calibration, automatic calibration and other high-end process technology and the integrated application of PDM, ERP, MES and other systems, to achieve the factory’s full-process information management and control, employees can real-time tracking of production output, quality, efficiency, progress and other indicators, through instant feedback, timely detection of problems, improve production, improve efficiency.

In the SMT production workshop, two German Siemens SMT automatic placement equipment and plug-in production line can complete 60,000~80,000 solder joints per hour, realising automatic loading, automatic printing and AOI automatic inspection ….. Household alarm automatic assembly production line, the average output of a standardised product every 6 seconds ……

This is the audit experts in the Chicheng electric production workshop to see the scene – with the help of digital, intelligent means, Chicheng Electric has achieved real-time control of the production process, Chicheng ‘smart’ is becoming a reality. Through the review, the audit team experts on the Chicheng Electric fusion of two management system work to give affirmation, confirmed Chicheng Electric supervision and audit site audit passed, agreed to recommend Chicheng Electric continue to maintain the fusion of two management system certification.

Empowering with ‘numbers’, improving quality with ‘wisdom’. As a gas environment safety products and system solutions provider, the development of new quality productivity is the need for enterprise upgrading, but also the company focuses on the main business, to achieve intelligent, green development needs. Riding the east wind of the digital economy, Henan Chicheng Electric Co., Ltd. in-depth promotion of the integration of information technology and industrialisation, after years of development, completed from the ‘manufacturing’ to ‘intellectual’ upgrade, and successfully ranked among the national speciality and speciality new ‘Small giant’ enterprise ranks.

Chicheng Electric in the increase of intelligent manufacturing at the same time, and constantly optimise the internal management and technological transformation. At present, Chicheng Electric built to independent research and development as the core of the business system, mastered the ‘gas sensing, gas monitoring, Internet of Things platform’ and other aspects of monitoring technology and software algorithms, technology and other high-end technology, successfully developed a series of ‘fist’ of industrial and commercial gas detectors, gas alarm controllers, civil gas detectors, intelligent sensors and so on. Sensors and a series of ‘fist’ products, to create a rich product matrix.

At the same time, Chicheng Electric also through the application of 5G, the Internet, big data, cloud computing and other high-tech, to create a smart gas, smart industry, smart municipal, smart corridor, smart manholes and other cloud platforms, to achieve real-time monitoring of gas safety, timely early warning, risk assessment, data management and other functions, to help various fields of production safety to digital, intelligent transformation and upgrading.

The improvement of manufacturing level, promote the reform of enterprise management system. Chicheng Electric through the implementation of ‘lean management’, ‘lean R & D’, ‘lean production’ and other management modes, formed from the receipt of orders to product design, process, manufacturing, quality control, Logistics and transport, after-sales support and other production cycle and link of the whole process of intelligent application, with standardisation, pull production, U-shape production line transformation and other methods and tools, to achieve lean, precise, accurate as the core of the rapid response to the integration of 5S standardised management and collaborative control.

The effective implementation of Chicheng Electric two-chemical fusion management system helps optimise resource allocation, improve production efficiency and product quality; at the same time, it can reduce operating costs and enhance market share; it helps the company to form a new quality of productivity, enhance the overall competitiveness of enterprises, and realise sustainable and high-quality development of enterprises.

Empowering gas environmental safety with intelligent technology is the engine of Chicheng Electric’s adherence to the road of scientific and technological strength of the enterprise. In the future, Chicheng Electric will continue to implement the requirements of the integration of the two management system, continue to strengthen the digital transformation efforts, and constantly improve the ‘number of intelligent empowerment’ system construction, unswervingly take the road of new industrialisation, for the consignment to go all out!