Industrial gases, known as the “blood of industry,” are essential raw materials for the modern industrial system and are widely used in strategic sectors such as steelmaking, petrochemicals, aerospace, and electronics and semiconductors. However, if this “blood” gets out of control, it can lead to accidents such as explosions, poisoning, and suffocation. In mild cases, these can paralyze production lines, damage equipment, and force companies to suspend operations and undergo restructuring, resulting in significant economic losses. In severe cases, these can lead to catastrophic consequences with widespread casualties. Companies will not only face hefty compensation costs but also face severe legal action and even market elimination.

The “Triple Dangers” of Gas Leakage in Storage and Transportation

Combustible gases such as methane (CH₄), hydrogen (H₂), and ethylene (C₂H₄) can rapidly mix with air to form explosive clouds when leaked, which can explode when exposed to static electricity, sparks, or high temperatures.

Toxic gases: Leaks of toxic gases such as hydrogen sulfide (H₂S), chlorine (Cl₂), and ammonia (NH₃) can enter the human body through inhalation, skin contact, or eye irritation, directly attacking the nervous, respiratory, and circulatory systems. These hazards are both insidious and cumulative.

Asphyxiating gases: Leaks of asphyxiating gases such as nitrogen (N₂), carbon dioxide (CO₂), and argon (Ar) can dilute oxygen or displace air, leading to localized hypoxia. While leaks are typically odorless and pose no explosion risk, the lack of respiratory protection can cause unconsciousness and secondary casualties.

LNG tankers face the “extremely low temperatures + high risks” challenge:

The lethal threat of -162°C: LNG leaks can instantly freeze human tissue, causing severe frostbite and even amputation.

Vapor Cloud Explosion Risk: 1 cubic meter of LNG leak can vaporize into 600 cubic meters of flammable gas, forming a flammable vapor cloud that can easily ignite in the presence of a fire source.

Environmental Damage Chain: Leaked LNG can disrupt soil microbial activity, kill vegetation, and contaminate groundwater.

Safety Precautions During Storage and Transportation

01 Equipment Maintenance: Analyze the physical and chemical properties of the equipment and implement appropriate maintenance measures. Analyze the equipment’s process characteristics, fully understand its operating principles, and reduce operational risks.

02 Ensure static electricity protection for storage and transportation equipment: Ensure stable grounding points, bridge any threaded connections with high resistance, and ensure the grounding resistance of oil and gas storage and transportation equipment is within the specified range.

03 Install Safety Devices: Install monitoring instruments to monitor temperature, pressure, liquid level, flow rate, and other parameters during storage and transportation. Set alarms and interlocks for critical parameters. Also, equip leak detection alarms for flammable and toxic gases in areas prone to leakage.

04 Standardize Hot Work: Strictly follow operating procedures and verify the appropriate environment for hot work before any work begins. During operations, the site must be thoroughly inspected and cleaned; after operations, power must be turned off promptly and any hot equipment removed.

Portable Gas Detectors

From “Passive Response” to “Proactive Prevention”

During storage and transportation, the “golden time” to respond to gas leaks is often only a few minutes, and portable gas detectors are crucial equipment in this race against time. Portable gas detectors are essential tools for ensuring operational safety, and their technical features and application scenarios vary depending on the device type. Based on the type of gas detected, they can be categorized as single-gas, dual-gas, and multi-gas detectors. Based on the gas sampling method, they can be divided into diffusion-type and pump-type gas detectors.

Functional Advantages

High Accuracy and Fast Response

Chicheng Electric’s portable gas detectors utilize high-quality sensors with sensitive response and strong reliability, enabling them to detect toxic and hazardous gas leak concentrations at any time.

Full-Scenario Coverage

Diffusion-type: Relying on the natural diffusion of gas, the contact sensor is suitable for rapid screening in open spaces, easy to operate, and suitable for large-scale area inspections.

Pump-Suction Type: A built-in micro-pump actively extracts air samples, precisely controlling the sampling flow rate. This makes it suitable for confined spaces or remote monitoring applications.

Pistol-Suction Type: Equipped with an extended, flexible probe, it supports manual, directional sampling and can penetrate hidden areas such as equipment gaps and pipeline interiors. This flexibly adapts to complex working conditions and improves the efficiency of identifying hidden risk points.

Simultaneous Multi-Gas Monitoring

Chicheng Electric’s composite gas detectors can simultaneously detect up to six types of gases, meeting the needs of complex working conditions.

Adaptable to Extreme Environments

Chicheng Electric’s portable gas detectors all have high-level explosion-proof certifications and IP protection ratings, effectively resisting dust, water, and explosions, and operating stably in a variety of harsh environments.

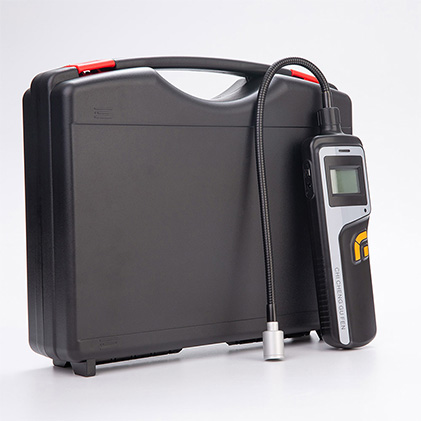

Chicheng Electric GC510 Portable Gas Detector

Chicheng Electric’s GC510 series portable gas detectors are available in both gun-suction and pump-suction types. Equipped with high-precision sensors and flexible configurations, they offer fast response times, excellent stability, high sensitivity, compact size, and light weight.

Upgraded Algorithm for High Accuracy

The GC510 portable gas detector utilizes high-performance sensors and newly upgraded software algorithms, delivering long-term, stable, and high-precision detection. Its intelligent dual-range detection (PPM/%LEL) allows real-time monitoring of various toxic, hazardous, and combustible gas leak concentrations in the environment, ensuring personal safety.

Flexible Probe for Convenient Detection

The GC510 features an extended, flexible probe that can be bent freely, making it easy to inspect even small, confined spaces. A newly designed sensor cover provides effective shock absorption and enhances instrument stability.

Full Functionality for Smarter Operation

The GC510 portable gas detector includes multiple features, including password management, real-time clock display, two-level alarm setting, alarm record storage, and alarm record query, making it easy for administrators to use.

Rugged and Durable, with Quadruple Alarm Indicators

The GC510 portable gas detector is constructed from special high-strength ABS engineering plastic, making it durable, waterproof, dustproof, non-slip, and explosion-proof. It features quadruple alarm indicators: audible, visual, vibration, and an LCD display, providing enhanced protection and peace of mind.

Convenient to carry and comfortable to hold

The grip, designed based on the natural structure of the human hand, and the size and placement of the buttons make it easy for operators to switch between left and right hands, allowing for accurate single-handed operation.

Strictly adhere to safety red lines and build a solid defense line for life. Gas leak prevention and control, as well as emergency response, is a race against time. Only by building a dual insurance system of “technology + management” can companies overcome dangers and protect lives and property when crises strike.