The sewage treatment plant is the kidney of the city. Generally, sewage is subject to sedimentation and aeration (aeration is a means to make air and water in strong contact, which is to dissolve oxygen in the air in the water, or release unwanted gas and volatile substances in the water into the air). Through activated sludge and microbial treatment, the pollutants in the water body are cleaned step by step, disinfected with chlorine, and then discharged into normal water body after meeting the standard.

Sewage treatment plant is a complex system composed of multiple unit processes. The cost and efficiency of each unit process are interrelated and affect each other, and ultimately determine the cost and efficiency of the whole system. The general objective of wastewater treatment is to remove suspended solids and improve oxygen consumption (i.e. stabilize organic matter), sometimes disinfection and further treatment. The treatment of industrial wastewater focuses on the removal or transformation of oils, suspended solids, heavy metals and organic substances that hinder the operation of urban sewage plants or have high residues, as well as the adjustment of pH value. Sewage treatment facilities are very important infrastructure in modern cities and play a very important role in protecting the water environment. Therefore, strengthening the construction and maintenance of sewage treatment facilities is of great significance to the sustainable development of modern cities.

The structure of sewage treatment plant is complex, and the sewage treatment process is complex and diverse, so it will produce a variety of toxic and harmful gases. Toxic and harmful gases can be generated or exist in various clean water tanks, thickening tanks, underground sewage, sludge gate wells, stagnant sewage tanks and disinfection facilities in the inlet channel (pipeline) of the sewage treatment plant. Common ones include hydrogen sulfide, hydrogen cyanide, carbon monoxide, carbon dioxide, chlorine, ozone, chlorine dioxide, methane, hydrogen, etc. Toxic gas will cause certain harm to human body. When combustible gas and air mix to a certain proportion, they will burn or even explode in case of open fire.

Solution

1. scheme overview

The following solutions are formulated for the pain points of the sewage treatment plant industry.

Environmental equipment monitoring system: various sensors such as combustible gas and toxic gas detection alarms are placed in the sewage treatment plant to monitor various gas states and environmental parameters in real time during the sewage treatment process.

Data transmission system: there are two data transmission modes, one is wired transmission, the other is wireless transmission.

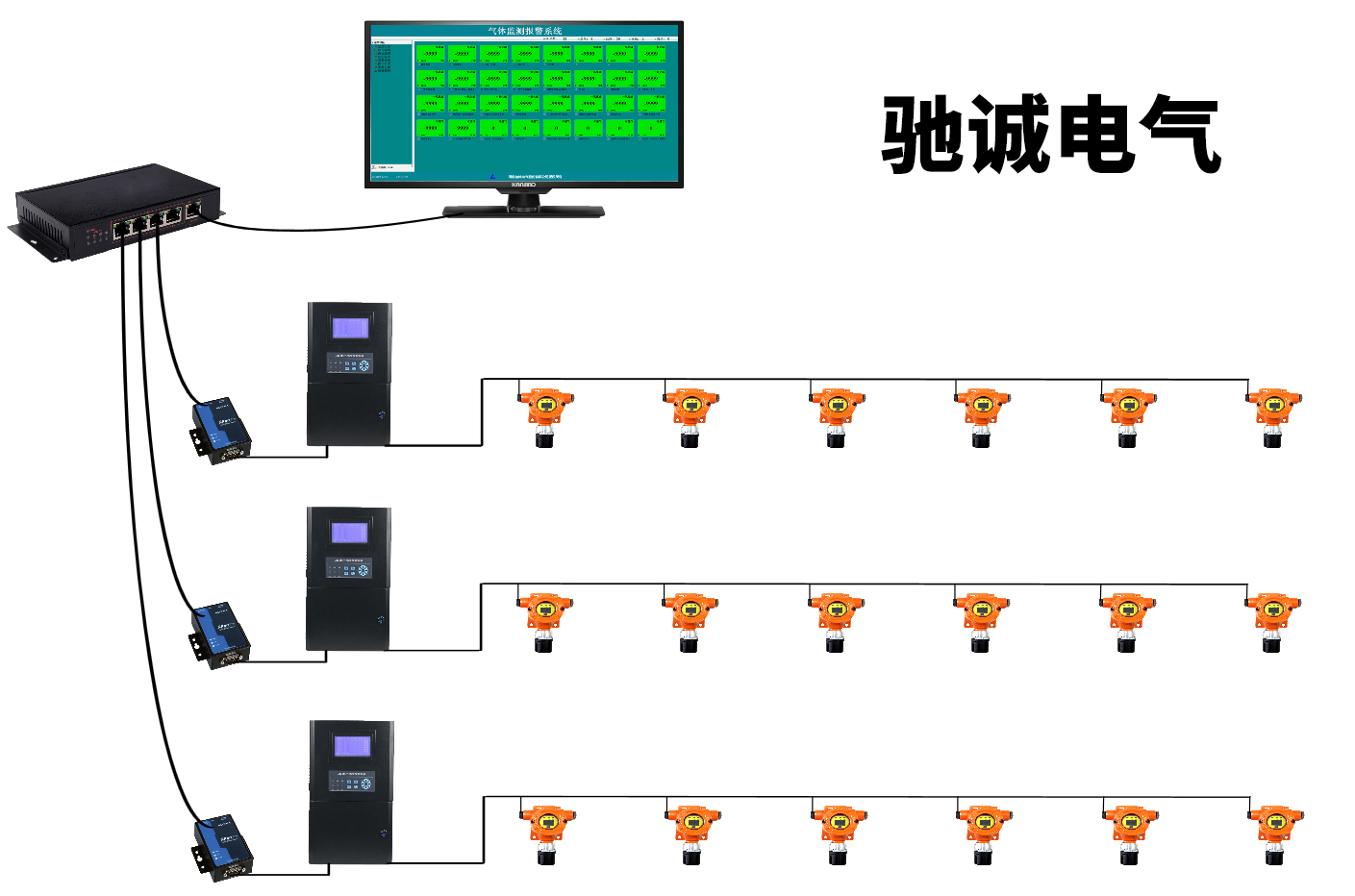

1) Wired transmission: the gas controller can output RS485 signal, which is converted into RS232 signal by the converter and transmitted to the computer terminal or SIS system.

2) Wireless transmission: the gas controller can wirelessly transmit the collected signal to the computer terminal or SIS system through 2g/4g network.

Data monitoring system: the data monitoring system is mainly composed of data server, TV wall, central monitoring server, computer client, mobile app, etc.

2. system composition

Solution for toxic and harmful gas in sewage treatment plant

3. system functions

1. Support simultaneous monitoring of multiple hosts and automatic switching of monitored hosts.

2. It supports flexible addition or deletion of the number of detectors and flexible grouping of detectors.

3. It supports customized modification of detector name, address, gas type, unit and remarks.

4. Support the alarm prompt function, automatically save the alarm monitoring information and manually export the alarm information to excel.

5. Support detector curve display. You can view the history by day, month and year.

6. Support the browser to view the monitoring interface of the device host through the remote LAN.